BIOTECHSA

RENEWABLE SOLUTIONS

Gasiflex™ 50 and BioDiesel solutions from BioDiesel Technologies® (BDT)

BioTechSA in partnership with Farmet

Our team remains dedicated to the further development of secure, economical and sustainable energy supplies. BDT forges its future into the next chapter of renewable energy sources by focusing on decarbonisation, decentralisation and digitisation.

- Decarbonisation

- Decentralisation

- Digitisation

With Gasiflex™ 50, users can be efficient, economically smart and independent with a 3-in-1 biomass to energy technology that grants gasification, electricity and heating solutions.

Our BioDiesel Technologies® allows for a 2-in-1 solution: a system that allows for the disposal of used oils from kitchens – to be repurposed into sustainable oil fuels for other industries.

Gasiflex™ 50

- Electric Power: 49 kWel

- Thermal Power : 85 kWth

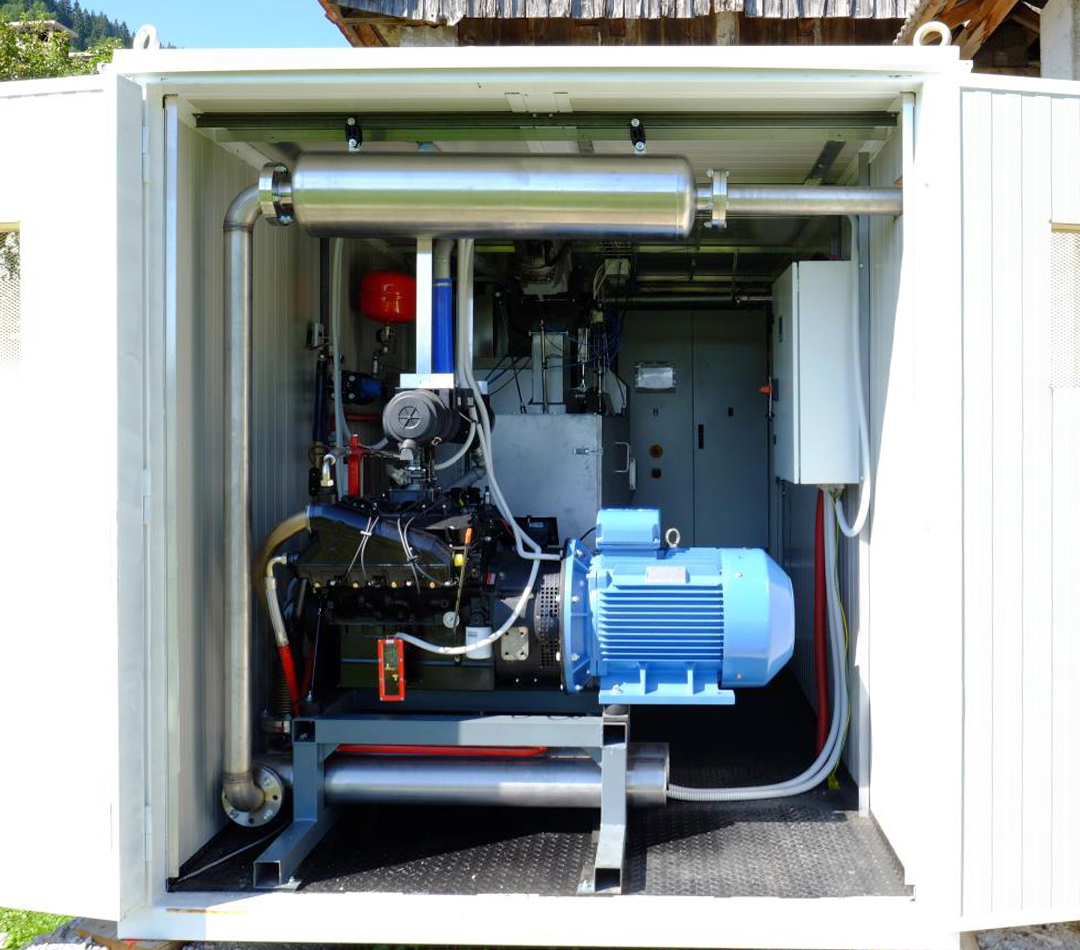

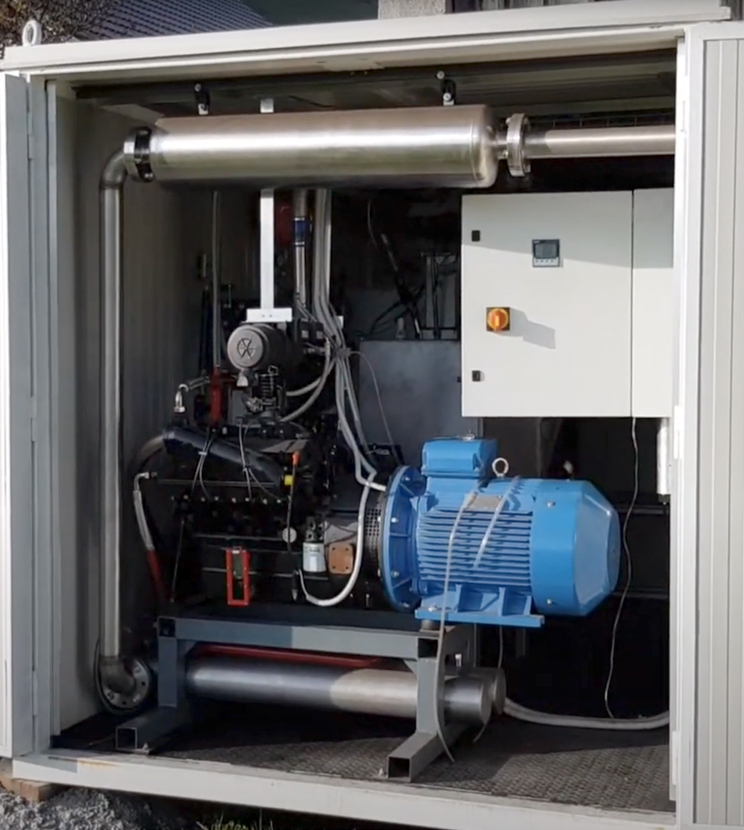

The GasiFlex50 power unit built into 20ft

container is a unique “3-in-1” solution of a

gasifier, a co-generator, an integrated dryer.

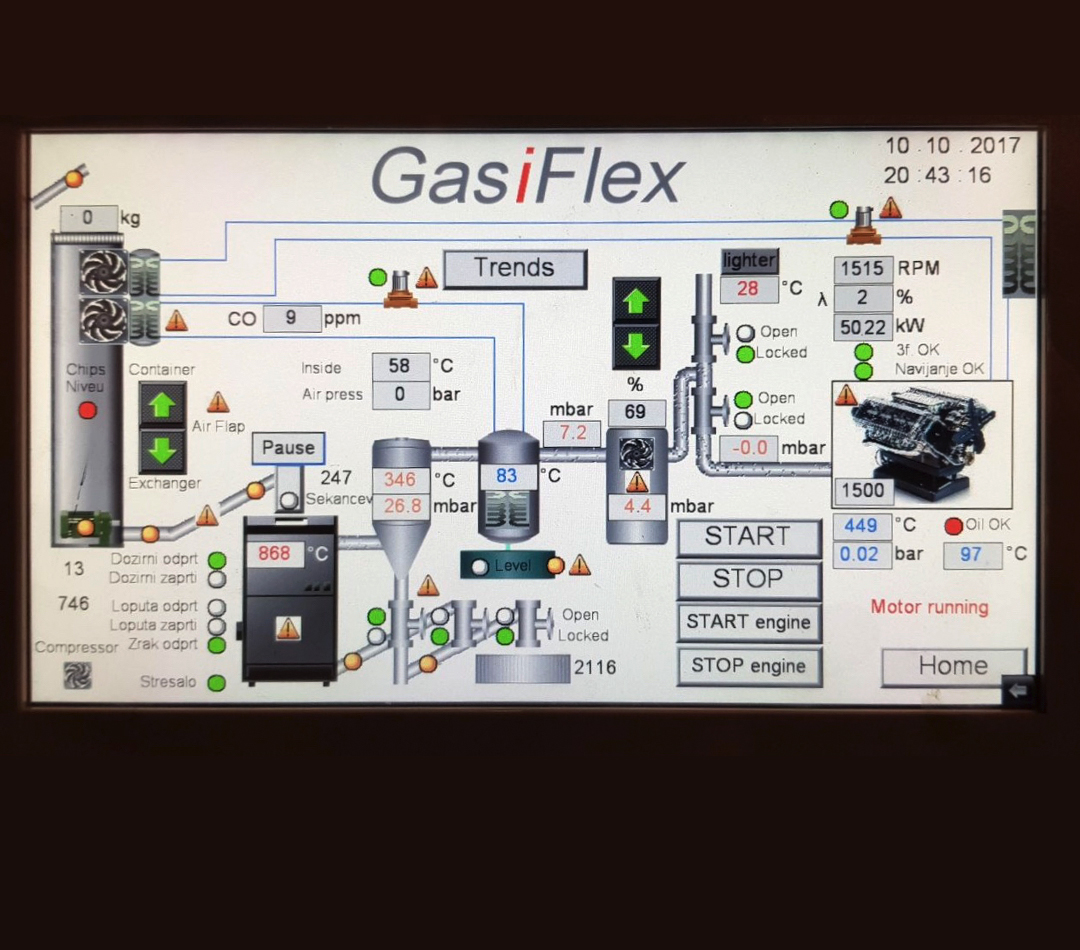

The high degree of automation enables the

packaged technology to be deployed without

constant staff and to be monitored constantly

by remote surveillance. The unique biomass

based patented technology accepts the

input fuel materials with high flexibility and

tolerance.

MAIN FEATURES

- Fully Automated, Remote Monitoring

- Integrated Safety Regulations

- Easy Maintenance & International Service

- Fast Installation and Start-Up

THERMIFLEX COMBUSTION

- Moving Grate System

- Air Distribution

- Temperature Control

- Automatic Regulation

WASTE BIOMASS PROCESSED

- Wet Wood

- Broiler Litter

- Waste Biomass from Wood Processing

CPU 3000F BIODIESEL PRODUCTION UNIT

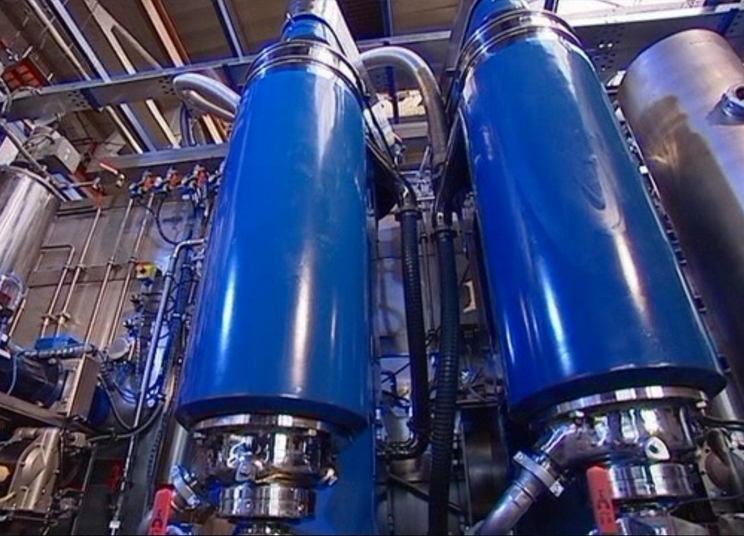

The CPU 3000F is a “plug and play” complete production unit itself, assembled and tested prior to delivery in our own production facility. The operation of the CPU 3000F is fully automated, remote control and remote operating intervention is available. The CPU 3000F is a standardized, combined unit of free fatty acid reduction and transesterification, which is designed for 24 hour/7days operation by personnel trained by BDTech s.r.o.

The CPU 3000F is housed in a standardized 20 ft container, with an approximate weight of 10 000 kg. The infrastructure of the project is the simplest possible solution, to make this venture flexible, highly efficient and profitable. Simple infrastructure also enhances easy obtaining of permits or problem‐free relocation if needed. We recommend using “plastic”‐ decanter tanks and IBC container tanks for storage